Visit to UF Water Reclimation Facility with Mr. Fender

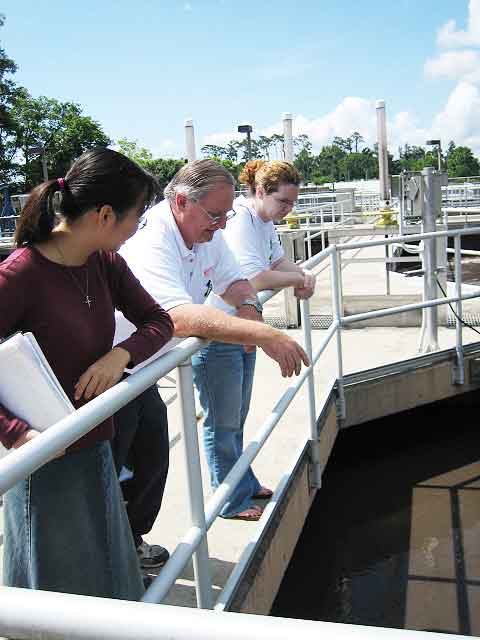

On June 22th, 2006, the Bioenergy Interns of UF attended a tour of the UF Waster Reclamation Facility.

The facility is located at the corner of Museum Road and North-South Drive, on the UF campus just south of the New Physics Building. This 12- million dollar wastewater plant was constructed in 1994 with a capacity of 3 million gallons per day. This facility receives all the waste waters of the university main campus. Once treated by the plant, the water is either discharged into Lake Alice for deep well injection or directed to sprinklers for irrigation.

The following is a twofold description. One description is the interns trailing the waster water from the beginning of the treatment to the end. The other description is what the interns really saw while on the tour.

A drop of wastewater begins at the intake pipe where the flow is constantly monitored. This drop of water goes through a preliminary treatment called a bar screen. The screen is like a rake, where it captures large debris like sticks, plastics and papers. A claw then grabs onto this captured material and sweeps it into a dumpster.

This wasted material is then mixed with lime to raise the pH and reduce the odor. Then perfume of the scent gbubblegumh was sprayed onto the mixture to mask the odor.

As for the wastewater, it goes through a primary clarifier where fine particles like dirt and sand can be removed. This machinery was in maintenance when we were there, so we did not see it in action.

After all the primary treatment, the wastewater goes into a splitter box where it can either go into the east tank or the west tank. The tanks are identical, and the interns can see that the plant is mirror imaged for the next few processes. The plant is designed with two completely separate but identical unit so to allow maintenance without shutting down the entire operation.

The tanks that the waste water goes into are activated sludge tanks. Activated sludge is where microorganisms are mixed with wastewater to remove nutrients. The wastewater is brown color here, and one can see what looks like suspended flakes, floc, in the water, not to mention the horrid smell. The flakes are the microorganisms, eating away at the organic matter and nutrients of the wastewater, cleaning it in the processes. Air is induced into the water by a brush aerator, which looks paddles on the steam boats along the Mississippi. This makes the reaction aerobic, subsequently causing the oxygen molecules to bond to nitrogen atoms, making nitrate.

After the waste water droplet spends some quality time in this tank (a few hours), it goes into an anoxic tank. With the lack of oxygen in this tank, the microorganisms pluck the oxygen molecule off the nitrate, eventually releasing the nutrient nitrogen into the atmosphere as gaseous nitrogen.

So the waste water gets re-oxygenated before it is sent to a secondary clarifier. The speed of water really slows down here. It is pumped into the clarifier from the bottom. The floc from the activated sludge is added with a polymer where it can form larger flocs and settle to the bottom. This sludge is either wasted or sent back to the front of the plant as inoculating media. The processed water is skimmed from the top of the clarifiers.

When we saw it, there was some vegetation growing on top of one of clarifier. The plant operator tells us that this vegetation is removed during maintenance when they shut that side of the plant.

After the clarifier are two polish processes. They are the sand filter and chlorination.

The sand filter is dyna-sand, a particular grade of sand that is about 1mm in size. This is like a very fine screen where the waste water is further filtered. Once it is done, it goes into chlorination.

Chlorination happens by adding sodium hypochlorite into the wastewater. This is done to reduce the pathogens in the influent. After this point, the wastewater is not called wastewater but reclaimed water. It takes a drop of wastewater about eighteen to twenty six hours from the time it enters the plant, to the end product.

The end product is later stored in a tank at the end of plant for either watering our beautiful UF campus or a deep well injection point out on Lake Alice.

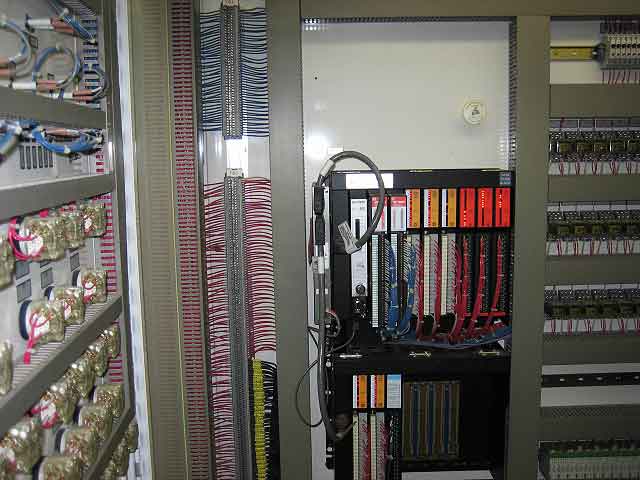

All the units and processes above cannot be done without supporting machinery. One of the first machinery we were introduced to was the programmable logic computer.

The programmable logic computer is the central intelligence of entire plant, automating utilities of the plant. From this computer, the plant operator can observe and record the flow rate into the plant, through the various pumps and out of the plant. The plant operator can also turn on and off the units like the air blower for the aerobic tank, the pumps, and also the gates directing the flows of the wastewater.

There was one building that housed the loud engine for the blower and the backup generator for the plant. The backup generator had enough power to operate the plant, but not to start up the plant.

One air-conditioned structure is in the middle of the plant is the interchange between the manual switches and the automated computerized switches. If the logic computer mentioned above fails, the operators can still control and regulate the plant processes through the keys, knobs, and switches.

The last place of interest is the dump yard for waste sludge. In here, the wasted biosolids of 1% solids content from the clarifiers are funneled into a belt press, making the solid content into 3%. There is also a non-operational multi-million dollar dryer that does not work. The plant said that the dryer was a prototype and the engineer did not factor in the expansion joints necessary to compensate for heat drying. Also, there were many complaints of the odor when the dryer was operational.

That was the official tour of the UF Water Reclamation Facility. We learned and saw each process and its supporting units that are required to clean our wastewater. We like to thank Chuck Fender for taking time out of his day to show us around.

Website of Water Reclamation Facility

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|